As an Amazon Associate, I earn from qualifying purchases

Refrigerant blends can leak from a system through faulty seals or corroded lines. Improper installation or physical damage often leads to such leaks.

Refrigerant leaks are a significant issue that can impact the efficiency and performance of your cooling system. It’s crucial to understand how these leaks occur and the steps to prevent them. Recognizing the signs of a leak early can save you from costly repairs and environmental harm.

Proper maintenance and regular check-ups by a professional can help ensure that your system remains sealed and functional. Keep in mind that different types of refrigerant blends may have varying impacts on the environment and require specific handling procedures. Addressing leaks promptly not only extends the life of your equipment but also contributes to energy conservation and reduces greenhouse gas emissions.

The Basics Of Refrigerant Blends

Understanding refrigerant blends is key to maintaining and repairing cooling systems. These blends are crucial for environmental safety and system efficiency. Let’s explore their composition and role.

Composition Of Refrigerant Blends

Refrigerant blends consist of two or more gases mixed together. Each gas in a blend serves a specific purpose, enhancing the overall performance of the refrigeration cycle. Common gases include R-410A, R-407C, and R-134a. These are not pure gases but combinations tailored for specific needs.

| Blend | Components |

|---|---|

| R-410A | HFC-32, HFC-125 |

| R-407C | HFC-32, HFC-125, HFC-134a |

| R-134a | Single Component |

Role In Cooling Systems

Refrigerant blends play a critical role in cooling systems. They absorb heat from the environment and release it elsewhere. This process keeps our homes, cars, and offices cool. Blends are chosen based on their efficiency and environmental impact.

- Absorb heat: Essential for cooling.

- Release heat: Completes the cooling cycle.

- Efficiency: Reduces energy use.

- Environmental safety: Less ozone depletion.

Each blend’s effectiveness and environmental impact guide their use in various systems. Choosing the right blend can lead to more efficient cooling and reduced environmental harm.

Credit: www.elitechus.com

Common Causes Of Refrigerant Leaks

The efficiency of your cooling system hinges on a sealed environment where refrigerant circulates. But leaks happen, compromising performance and efficiency. Let’s explore the typical reasons why refrigerant might escape from your system.

Material Fatigue And Corrosion

Refrigerant circuits suffer from wear and tear. Over time, this leads to material fatigue. Your system endures constant pressure changes. These fluctuations can weaken materials, causing small cracks or breaks.

Corrosion poses another threat. It eats away at metal components. Rust can form due to moisture or chemical exposure. This weakens the integrity of the cooling system.

- Vibration from the compressor can accelerate material fatigue.

- Chemical reactions with lubricants or contaminants may increase corrosion.

Faulty Installation And Poor Maintenance

A proper install is crucial for a leak-free system. Skilled technicians ensure every connection is secure. But, mistakes can happen. A system not installed correctly is prone to leaks.

Regular maintenance is equally important. It extends the life of your system. Without it, small issues can grow. Eventually, they lead to refrigerant leaks.

- Loose fittings or joints can be a direct result of poor installation.

- Lack of inspections might miss early signs of wear or corrosion.

- Dirty filters or coils force the system to work harder, increasing stress.

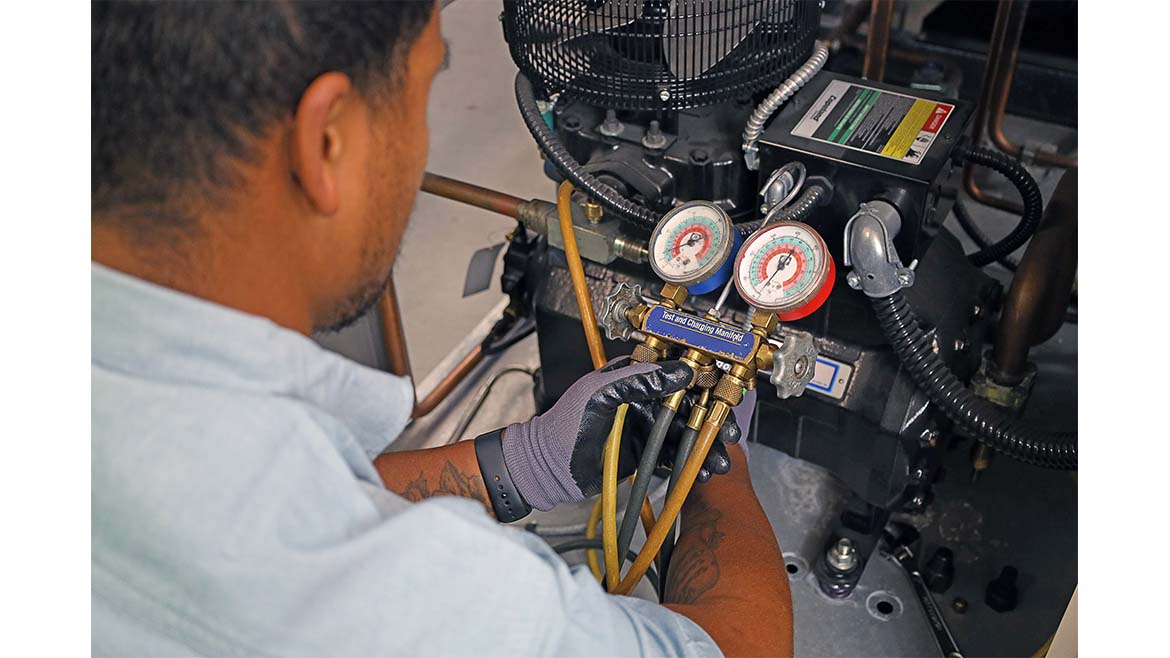

Detecting Leaks In Hvac Systems

Maintaining the integrity of HVAC systems is crucial for efficiency and safety. A common issue that affects these systems is refrigerant leaks. Detecting these leaks promptly is key to avoiding high energy bills and potential equipment failure. Let’s explore traditional and innovative methods for identifying leaks.

Traditional Detection Methods

Detecting refrigerant leaks has always been a high priority. The traditional methods include:

- Soap Bubble Test: Technicians apply a soap solution to suspected areas. Bubbles form if there’s a leak.

- UV Dye: A fluorescent dye is injected into the system. It glows under a UV light at leak points.

- Halide Torch: This tool detects chlorine-based refrigerants. A color change in the flame indicates a leak.

- Electronic Detectors: Devices that sense refrigerant gases. They signal a leak through audio or visual cues.

Innovative Leak Detection Technologies

With advancements in technology, innovative solutions have emerged. These include:

- Infrared Imaging: Cameras pinpoint leaks by detecting temperature differences.

- Ultrasonic Detectors: Devices that pick up the high-frequency sounds emitted by escaping gases.

- Automated Monitoring Systems: These systems continuously monitor and alert for leaks.

- Smart Sensors: Wi-Fi enabled sensors provide real-time data and notifications.

These technologies allow for quicker, more accurate detection, helping to maintain system performance and reduce environmental impact.

Credit: www.elitechus.com

Impact Of Refrigerant Leaks On System Efficiency

The efficiency of a cooling system relies heavily on the stability of its refrigerant levels. When leaks occur, they can significantly hamper the system’s performance. Understanding how these leaks impact efficiency is crucial for maintaining optimal operation.

Reduced Cooling Capacity

Refrigerant leaks lead to a loss of cooling power. This is because the refrigerant is the fluid that absorbs heat from the environment. With less refrigerant, the system struggles to maintain the desired temperatures, leading to inconsistent cooling and hot spots. This forces the system to work harder, often resulting in premature wear and tear on components.

Increased Energy Consumption

Energy use spikes when a system operates with a refrigerant leak. The equipment must run for longer periods to achieve the set temperatures. This increased runtime not only leads to higher energy bills but also puts added stress on the electrical components. In the long term, this can mean costly repairs and maintenance.

- Leaking refrigerant should be addressed quickly.

- Regular maintenance can help identify leaks early.

- Professional repair ensures system efficiency is restored.

Environmental And Regulatory Concerns

Refrigerant blends play a crucial role in cooling systems. Yet, they pose serious environmental risks when they leak. These substances can lead to ozone layer depletion and contribute to global warming. Regulations are in place to manage their impact. Let’s explore these concerns further.

Ozone Depletion And Global Warming Potential

Ozone depletion is a major environmental issue. Certain refrigerants break down ozone molecules. This thins the protective layer around Earth.

Refrigerants also have a Global Warming Potential (GWP). GWP measures how much a substance can warm the Earth. Higher GWP means more warming over time. Refrigerant blends often contain gases with a high GWP. When these gases escape, they trap heat in the atmosphere.

- HCFCs: Harmful to ozone, being phased out

- HFCs: Less ozone harm, but high GWP

- HFOs: Newer, with lower GWP

Compliance With Environmental Regulations

Businesses must comply with environmental regulations. These rules help protect our planet. They limit the use of harmful refrigerants. They also require proper handling and disposal.

Technicians need training to prevent leaks. They must know how to recover and recycle refrigerants. This helps reduce environmental damage.

| Regulation | Purpose | Impact |

|---|---|---|

| Montreal Protocol | Phase out ozone-depleting substances | Reduces ozone harm |

| Kigali Amendment | Phase down high-GWP refrigerants | Lowers global warming risk |

| EPA Regulations | Enforce proper refrigerant management | Prevents leaks, ensures safe disposal |

Companies can face fines if they break these rules. It’s important to stay informed and follow all regulations.

Best Practices For Leak Prevention And Management

Best Practices for Leak Prevention and Management are essential for maintaining refrigerant systems. Leaks not only impact the environment but also increase costs. Effective strategies help ensure systems run efficiently and safely. Let’s explore key practices for keeping your system leak-free.

Routine System Checks And Maintenance

Regular checks are the frontline defense against leaks. Here’s what you can do:

- Inspect – Look for signs of wear and tear.

- Test – Use detectors to find any leaks.

- Replace – Change out worn components promptly.

A schedule for maintenance keeps systems in top shape. Follow the manufacturer’s guidelines. Use checklists to not miss any steps.

Advancements In Refrigerant Management

New technologies help manage refrigerants better. Sensors can now detect leaks faster than before. Here are some innovations:

- Smart Sensors – Alert you quickly when leaks happen.

- Automated Systems – Shut down areas when a leak is detected.

- Data Analytics – Predict and prevent potential leaks.

Keeping up with tech upgrades can save time and money. It also protects the environment by reducing emissions.

Credit: www.amazon.com

Frequently Asked Questions

How Do Non-azeotropic Refrigerant Blends Leak From A System?

Non-azeotropic refrigerant blends can leak at varying rates due to their different vapor pressures, leading to changes in the remaining blend’s composition and performance.

Why Blended Refrigerants Leak At Uneven Amounts?

Blended refrigerants leak unevenly due to their varied boiling points, causing selective leakage of certain components over others.

Why Do Refrigerant Blends Leak At Different Rates?

Refrigerant blends leak at different rates due to their varying vapor pressures. Each component in a blend can evaporate at a distinct rate, leading to selective leakage.

When One Or More Of The Refrigerants In A Blend Leak At A Faster Rate Than Other Refrigerants In The Blend?

This occurs due to the phenomenon known as fractionation. Different refrigerants in the blend can have varying volatilities, causing some to leak faster than others. This alters the composition and efficiency of the remaining blend.

Conclusion

Understanding refrigerant leaks is crucial for system maintenance and environmental protection. By recognizing common leak points and implementing preventive measures, you can enhance system longevity and performance. Stay vigilant and proactive to keep your refrigeration system running smoothly and efficiently.

As an Amazon Associate, I earn from qualifying purchases