As an Amazon Associate, I earn from qualifying purchases

Understanding the optimal vacuum for a brake booster is crucial for maintaining effective braking performance and ensuring driver safety. The brake booster, an essential component in most modern vehicles, relies on engine vacuum to amplify the force applied to the brake pedal. By knowing how much vacuum is necessary, we can better appreciate how a relatively small effort from the driver translates into significant stopping power.

Interestingly, too little or too much vacuum can compromise braking efficiency. Typically, an ideal range falls between 18 and 22 inches of mercury (Hg). Falling below this range often means reduced assistance and a more rigid pedal feel, while exceeding it might point toward potential issues like leaks or system malfunctions needing attention. Grasping these benchmarks empowers vehicle owners and mechanics alike with the knowledge to effectively diagnose and optimize braking systems.

Importance of Brake Boosters

Brake boosters play a pivotal role in modern automotive safety, yet their importance often goes underappreciated. Imagine the anxiety of realizing that your brakes require significantly more effort to engage, just as you’re navigating a busy intersection or descending a steep hill. This is precisely where the brake booster proves invaluable—it amplifies the force applied to the brake pedal, allowing for smoother and more effective braking with minimal physical strain on the driver. It transforms an ordinary braking system into a responsive and reliable one, greatly enhancing your vehicle’s stopping power.

Another critical aspect of brake boosters is their ability to maintain performance consistency even when the engine vacuum fluctuates, such as during rapid acceleration or climbing steep grades. They buffer against varying driving conditions by ensuring sufficient vacuum for optimal braking performance. This reliability offers peace of mind for everyday driving and emergencies where every fraction of a second matters. By understanding the technical sophistication and practical benefits offered by brake boosters, drivers can better appreciate why maintaining adequate vacuum levels is crucial for both safety and comfort on the road.

Overview of Vacuum Requirements

When considering the optimal vacuum for a brake booster, one must acknowledge that it’s not a one-size-fits-all scenario. The general consensus in the automotive world is that most brake boosters require 15 to 20 inches of mercury (inHg) to function efficiently. However, this range can vary depending on vehicle specifications and conditions. Such variation underscores the importance of understanding your vehicle’s needs, whether you’re driving a lightweight, compact car or a heavy-duty truck.

Moreover, achieving the correct vacuum level extends beyond just hitting an ideal number; it’s also about maintaining stability under various engine loads and RPMs. Modern vehicles equipped with turbochargers or superchargers may present additional challenges since these components can affect available vacuum levels. Therefore, ensuring an uninterrupted supply often necessitates auxiliary devices like vacuum pumps or specialized manifolds—especially critical for consistent braking performance during demanding driving situations. Unlocking optimal braking efficiency may sometimes demand innovative solutions tailored to your vehicle’s unique dynamics rather than relying solely on manufacturer guidelines.

Understanding Brake Boosters:

Brake boosters are essential to a vehicle’s braking system, amplifying the force applied to the brake pedal and ensuring quick and effective stopping power. Understanding how much vacuum is needed for a brake booster to function optimally is crucial for maintaining safety on the road. The vacuum level required varies depending on the type of brake system used in the vehicle, with power brakes typically needing higher vacuum levels than manual systems.

When determining the ideal vacuum level for a brake booster, factors such as engine size, camshaft profile, and altitude must be considered. A common misconception is that more vacuum always means better braking performance; however, excessive vacuum can lead to overly sensitive brakes and potential wheel lockup in emergencies.

Finding the right balance between vacuum pressure and brake response is critical to achieving smooth and controlled stops without compromising safety or driving comfort. By understanding the intricacies of brake boosters and their vacuum requirements, drivers can ensure their vehicles operate at peak efficiency while enhancing the overall driving experience.

Role in Vehicle Braking System

In vehicle braking systems, the role of vacuum in a brake booster is often overlooked yet crucial. The vacuum generated by the engine plays a pivotal role in enhancing the braking system’s efficiency and responsiveness. It assists in multiplying the force applied to the brake pedal, allowing for smoother and more controlled deceleration.

The proper amount of vacuum is essential for optimal brake booster performance. Too little vacuum can result in a spongy brake pedal feel and reduced braking power, leading to potential safety hazards on the road. Conversely, excessive vacuum may cause abrupt or overly sensitive brakes, compromising overall stability and control. Consequently, maintaining an adequate vacuum level is paramount to ensure safe and effective vehicle operation.

Ultimately, understanding the significance of vacuum in a vehicle’s braking system illuminates its essential function in ensuring reliable stopping power and driver confidence on the road. By acknowledging this often underappreciated element, drivers can better appreciate and maintain their vehicle’s overall performance and safety standards.

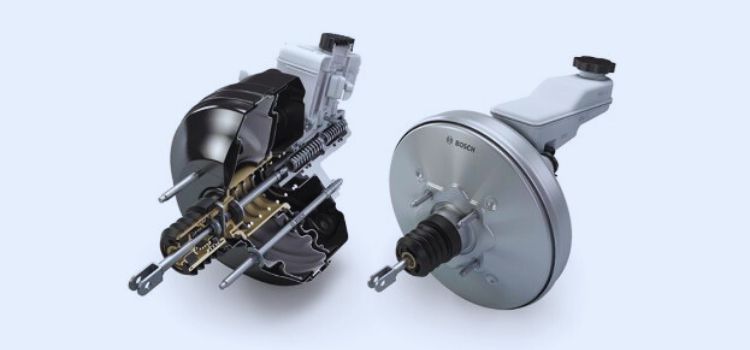

Types of Brake Boosters

The brake booster is a critical component in a vehicle’s braking system. They increase the force exerted on the brake pedal, providing faster stopping power. There are two main types of brake boosters commonly used on vehicles: vacuum brake boosters and hydraulic brake boosters. A vacuum brake booster uses the vacuum created by the engine’s intake manifold, while a hydraulic brake booster uses hydraulic pressure from the power steering pump to assist with braking.

Another type of brake booster gaining popularity is the electric vacuum pump-based booster, which doesn’t rely on engine vacuum like traditional systems. This innovative design provides consistent performance regardless of engine load or RPM, ensuring reliable braking in various driving conditions. Drivers seeking improved efficiency and control may opt for an electric vacuum pump-based brake booster for enhanced safety on the road.

When considering how much vacuum is needed for a specific type of brake booster, it’s essential to understand its operating requirements and compatibility with your vehicle’s engine. The right amount of vacuum ensures optimal performance and responsiveness in emergency braking situations, highlighting the importance of choosing a suitable brake booster based on individual driving needs and preferences. Understanding these distinctions among different types of brake boosters can help drivers make informed decisions when upgrading or maintaining their vehicle’s braking system.

Ideal Vacuum Levels

Understanding the ideal vacuum levels for a brake booster is crucial for maintaining optimal performance and safety in your vehicle. The balance between too much or too little vacuum pressure can significantly affect braking efficiency. While a vacuum level of 18-22 inches of mercury (Hg) is generally considered optimal for most vehicles, it’s important to note that this may vary depending on the specific make and model.

Excessive vacuum levels can lead to brake pedal stiffness, reducing responsiveness and increasing stopping distances. On the other hand, inadequate vacuum levels may result in a spongy brake pedal feel and reduced braking power. Regularly checking and adjusting the vacuum levels in your brake booster can help ensure smooth and reliable braking performance, ultimately enhancing overall driving safety.

By understanding the importance of maintaining the correct vacuum level in your brake booster, you can prioritize safety on the road and avoid potential braking issues. Consulting your vehicle’s manual or seeking professional assistance can help you determine the ideal vacuum level specific to your vehicle’s requirements, promoting efficient braking performance and peace of mind while driving.

Recommended Vacuum Range

Finding the sweet spot is crucial for optimal performance when it comes to the vacuum range for your brake booster. Typically, a vacuum range of 16-20 inches is recommended for most vehicles with power brakes. This range ensures enough suction force to assist in braking without causing excessive strain on the booster.

It’s important to note that a vacuum level below 16 inches may decrease brake assist and a spongy pedal feel. On the other hand, exceeding 20 inches of vacuum may cause the diaphragm in the brake booster to become overextended, potentially leading to premature wear and reduced effectiveness.

By understanding and maintaining the recommended vacuum range for your brake booster, you can ensure that your vehicle’s braking system operates at its best. Monitoring and adjusting the vacuum levels as needed can help prolong the life of your brake components and keep your car safe on the road.

Measuring Vacuum Levels

Measuring vacuum levels for a brake booster is critical to ensuring optimal performance and safety in your vehicle. The vacuum level required for a brake booster typically ranges from 16-22 inches of mercury (inHg), with some cars needing up to 25 inHg for efficient braking. Using a vacuum gauge is the most accurate way to measure the vacuum levels in your brake booster, providing real-time data on the system’s performance.

It’s important to note that insufficient vacuum levels can lead to decreased braking power and longer stopping distances, compromising the safety of your vehicle. On the other hand, excessive vacuum levels can cause the brakes to be overly sensitive, potentially resulting in abrupt stops and reduced control. Regularly checking and maintaining the correct vacuum level for your brake booster is crucial in ensuring smooth and safe operation on the road.

Factors Affecting Vacuum

Factors affecting the vacuum in a brake booster play a crucial role in the overall performance of the braking system. One key factor is engine displacement, as larger engines produce more vacuum due to increased airflow. Additionally, the condition of vacuum hoses and connections can significantly impact the vacuum level available for the brake booster to operate effectively. Any leaks or blockages in these components can decrease vacuum pressure, affecting braking efficiency.

Another vital factor influencing vacuum levels is engine load. When an engine works harder, such as during heavy acceleration or towing heavy loads, it may struggle to maintain consistent vacuum pressure for the brake booster. This can result in diminished braking power and longer stopping distances. Understanding these factors and ensuring proper maintenance of all related components is essential for optimal vacuum levels in a brake booster system.

Engine Performance Impact

The engine’s performance plays a crucial role in determining the effectiveness of various vehicle components, including the brake booster. A properly functioning engine is essential for maintaining the proper vacuum pressure to power the brake booster. When a motor is running smoothly and producing adequate vacuum levels, it ensures that the brake booster can operate at its optimal capacity, delivering efficient braking performance.

However, if the engine’s performance is compromised by issues such as a decrease in vacuum pressure due to leaks or mechanical problems, it can directly impact the effectiveness of the brake booster. A decrease in vacuum pressure can lead to reduced braking power and responsiveness, potentially compromising the vehicle’s safety. Therefore, it is essential for drivers to regularly maintain their engines to ensure that they are operating at peak performance levels and generating sufficient vacuum pressure for the brake system to function effectively.

In conclusion, understanding how engine performance impacts components like the brake booster highlights the interconnected nature of various systems within a vehicle. By prioritizing proper engine maintenance and promptly addressing any issues, drivers can enhance their vehicle’s overall performance and safety on the road.

Environmental Influences

Environmental influences play a crucial role in the performance of brake boosters. Extreme temperatures can affect the efficiency of the brake booster, with cold weather causing a decrease in power assist and warm weather leading to potential fluid leakage. Additionally, humidity levels can impact the rubber components of the brake booster, potentially causing deterioration and reducing its lifespan.

Air quality is another environmental factor that can influence brake booster performance. Contaminants in the air, such as dust, dirt, and moisture, can enter the braking system and impact its function over time. This highlights the importance of regular maintenance and checks to ensure optimal performance regardless of environmental conditions. Overall, being mindful of these environmental influences can help maintain the effectiveness and longevity of your vehicle’s brake booster system.

Common Issues and Solutions

Common issues with brake boosters often stem from a loss of vacuum pressure, leading to decreased brake performance and potentially dangerous situations on the road. One common problem is a vacuum leak in the system, which can cause damage to hoses or seals. This issue can be diagnosed by listening to a hissing sound when pressing the brake pedal.

To solve this problem, it’s crucial to inspect all vacuum lines and connections for any signs of wear or damage. Additionally, checking the brake booster check valve for proper functioning is essential in maintaining adequate vacuum pressure. By addressing these issues promptly, drivers can ensure their brakes operate at optimal levels and maintain safety on the road.

Identifying Low Vacuum Symptoms

When identifying low vacuum symptoms in a brake booster system, paying attention to warning signs can make all the difference in maintaining safe driving conditions. One common indication of low vacuum is a spongy or soft brake pedal that requires more pressure to engage. This decreased responsiveness can compromise the effectiveness of your brakes, putting you at risk on the road.

Another symptom to watch out for is an illuminated brake warning light on your dashboard. This indicator can signal a potential issue with the vacuum levels in your brake booster system and should not be ignored. Additionally, if you notice noisy or inconsistent braking noises while applying pressure on the pedal, it could be another sign of low vacuum levels affecting your braking performance. Being vigilant and proactive in recognizing these symptoms can help address any underlying problems promptly and ensure optimal safety while driving.

Troubleshooting Steps

When troubleshooting issues with your brake booster, you must start by checking for any signs of vacuum leaks. A common culprit is a deteriorated or disconnected vacuum hose, which can decrease braking effectiveness. If no visible leaks are found, using a vacuum gauge to test the amount of vacuum generated by the engine can help pinpoint potential problems.

Another step in troubleshooting involves inspecting the check valve that controls the vacuum flow to the brake booster. A faulty check valve can disrupt the proper functioning of the brake system and should be replaced if necessary. Additionally, testing the brake pedal for firmness and responsiveness can provide insights into whether there are underlying issues with the brake booster that need addressing. By diligently following these troubleshooting steps, you can ensure optimal performance and safety of your vehicle’s braking system.

Maintenance Tips

Maintaining your brake system is crucial for your vehicle’s safety and performance. One important component to monitor is the brake booster. When pressuring the brake pedal, regularly check for any signs of wear or damage, such as leaking seals or hissing noises. Additionally, ensure the vacuum hose connected to the booster is securely attached and free of cracks.

To ensure optimal functioning, it’s recommended that you test your brake booster regularly. A simple way to do this is to turn off the engine after a few pumps on the brake pedal—the pedal should become more burdensome if the booster is working correctly. Lastly, don’t overlook the importance of using high-quality brake fluid and following manufacturer recommendations for maintenance intervals. By staying on top of these maintenance tips, you can help prolong the life of your brake booster and ensure a safe driving experience.

Regular Inspection Practices

Regular inspection practices are vital for ensuring the safety and performance of your vehicle’s brake booster. It is recommended that you visually inspect the brake booster on a regular basis for any signs of leaks, cracks, or damage. Additionally, checking the vacuum hose connections and ensuring they are secure can help prevent air leaks affecting the booster’s functionality.

Furthermore, conducting a vacuum test using a handheld vacuum gauge can provide valuable insights into the health of your brake booster. By measuring the amount of vacuum pressure generated when applying the brakes, you can determine if there are any issues with the booster or if it is operating within optimal parameters. Regular inspections and maintenance of your brake booster ensure safe driving conditions and extend its lifespan, saving you time and money in potential repairs.

Ensuring Optimal Performance

Ensuring optimal performance of your vehicle’s brake booster is crucial for maintaining safety on the road. One key factor to consider is the amount of vacuum that the brake booster receives. The ideal vacuum level can vary depending on your vehicle’s make and model, but generally, a vacuum level between 16 and 20 inches of mercury is recommended for most vehicles.

Properly maintaining and monitoring the vacuum levels in your brake booster can help prevent issues such as decreased braking performance, spongy brakes, or even complete brake failure. Regularly checking for leaks in the vacuum system and ensuring all connections are secure can help maintain optimal performance. Additionally, investing in a quality vacuum gauge to accurately measure the vacuum levels in your brake booster can provide valuable insights into its overall health and functionality. By staying proactive and attentive to the needs of your brake booster, you can ensure that it continues to perform at its best whenever you hit the road.

FAQ

1. How much vacuum pressure is needed for a brake booster to function properly? The typical vacuum pressure needed for a brake booster to function properly is around 16-18 inches of mercury (inHg).

2. What happens if there is not enough vacuum pressure for the brake booster? If there is not enough vacuum pressure, the brake booster may not provide enough assistance to the brake pedal, resulting in a harder pedal feel and reduced braking performance.

3. How can I measure the vacuum pressure for my brake booster? You can measure the vacuum pressure using a vacuum gauge connected to the vacuum hose leading to the brake booster.

4. What can cause a decrease in vacuum pressure for the brake booster? Possible causes of decreased vacuum pressure include vacuum leaks, a faulty vacuum pump or hose, or engine-related issues affecting vacuum production.

Conclusion

In conclusion, understanding the optimal vacuum level for your brake booster is crucial in maintaining the efficiency and safety of your vehicle’s braking system. While manufacturers typically recommend a vacuum level between 16 and 20 inches Hg, factors such as altitude, engine size, and driving conditions may affect this recommendation. Fine-tuning the vacuum pressure can significantly impact brake performance, with too little vacuum leading to poor braking power and too much, causing potential damage to the seals.

Recap and Final Thoughts

In conclusion, the vacuum for a brake booster plays a critical role in ensuring efficient braking performance in vehicles. By providing the necessary assistance to the brake system, the vacuum enables smoother and more responsive braking, enhancing safety on the road. It is essential to maintain optimal vacuum levels to prevent any potential issues with braking effectiveness.

As an Amazon Associate, I earn from qualifying purchases