As an Amazon Associate, I earn from qualifying purchases

Brake boosters are crucial in modern vehicles, enhancing braking power and ensuring safer driving experiences. Understanding the vacuum requirements of brake boosters is essential for maintaining optimal functionality and vehicle safety. This article delves into the intricacies of brake boosters, their operation, and the importance of maintaining proper vacuum levels.

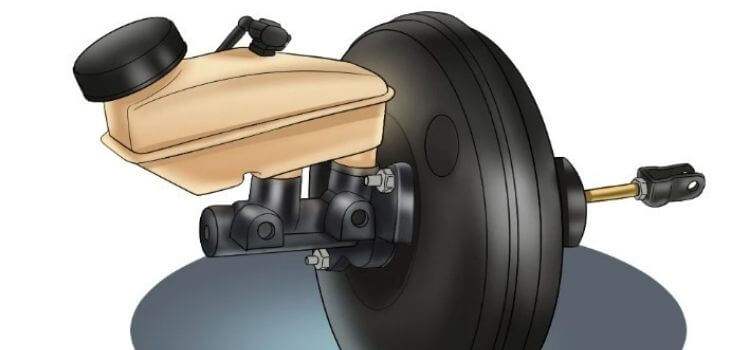

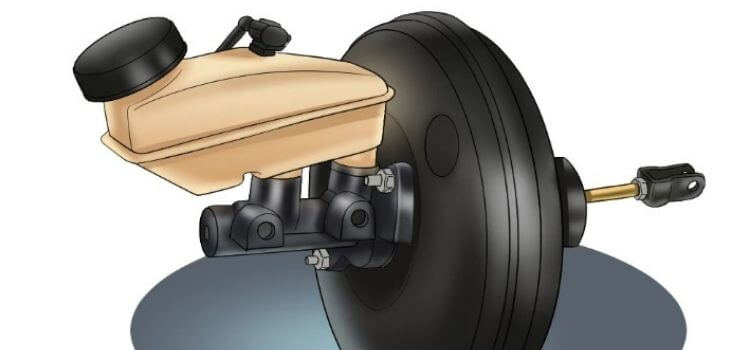

What is a Brake Booster?

Function of a Brake Booster

A brake booster amplifies the force applied to the brake pedal, making it easier to engage the brakes. It uses a vacuum created by the engine to reduce the effort required by the driver, ensuring efficient and responsive braking.

Types of Brake Boosters

- Vacuum Brake Booster: The most common type, using engine vacuum to enhance braking force.

- Hydraulic Brake Booster: Utilizes hydraulic pressure from the power steering pump.

- Electric Brake Booster: This uses an electric motor to create the necessary pressure, which is increasingly common in hybrid and electric vehicles.

How Brake Boosters Work

Basic Operation

Brake boosters use differential pressure to assist braking. When the brake pedal is pressed, the vacuum in the booster decreases, allowing atmospheric pressure to push on a diaphragm, thereby amplifying the force applied to the brake master cylinder.

Role of Vacuum in Brake Boosters

The vacuum is essential for creating the differential pressure that aids in braking. The booster cannot function correctly without adequate vacuum, leading to increased brake pedal effort and reduced braking efficiency.

Components Involved

The diaphragm, check valve, push rod, and vacuum source are key components. Each part plays a vital role in ensuring the booster operates effectively.

Importance of Vacuum in Brake Boosters

Functionality and Performance

Proper vacuum levels ensure the brake booster operates efficiently, providing the necessary force to engage the brakes with minimal effort.

Safety Implications

Adequate

braking. Insufficient vacuum can lead to brake failure or significantly increased stopping distances, posing severe safety risks.

Effects of Insufficient Vacuum

Low vacuum levels result in more arduous brake pedal effort, longer stopping distances, and potentially a complete loss of braking assistance, compromising vehicle safety.

Ideal Vacuum Levels for Brake Boosters

Standard Vacuum Requirements

For optimal performance, most brake boosters require a vacuum level of 18-22 inches of mercury (inHg). This range ensures adequate assistance under various driving conditions.

Factors Influencing Vacuum Needs

Engine size, type, and condition can affect vacuum levels. High-performance engines or engines with significant modifications may have different vacuum requirements.

Manufacturer Specifications

Always refer to the vehicle manufacturer’s specifications for the precise vacuum requirements of your brake booster. These specifications are tailored to ensure optimal performance and safety.

Symptoms of Insufficient Vacuum

Increased Brake Pedal Effort

One of the first signs of insufficient vacuum is a noticeable increase in the effort required to press the brake pedal.

Longer Stopping Distances

Reduced braking assistance results in longer stopping distances, which can be dangerous in emergencies.

Warning Signs on Dashboard

Many modern vehicles have warning systems that alert the driver to vacuum-related issues, such as a brake system warning light.

Causes of Low Vacuum in Brake Boosters

Engine-Related Issues

Vacuum levels can be affected by engine performance issues, such as leaks, misfires, or low compression.

Leaks in the Vacuum System

Leaks in hoses, connections, or the brake booster can lead to insufficient vacuum. Regular inspection is crucial to identify and address these leaks.

Faulty Brake Booster

A malfunctioning brake booster can fail to maintain adequate vacuum, requiring repair or replacement.

Diagnosing Vacuum Issues in Brake Boosters

Tools and Equipment Needed

You will need a vacuum gauge, diagnostic scanner, and essential hand tools to diagnose vacuum issues.

Step-by-Step Diagnostic Process

- Check for Vacuum Leaks: Inspect hoses and connections for signs of wear or damage.

- Test Engine Vacuum: Use a vacuum gauge to measure the engine vacuum when idle.

- Inspect Brake Booster: Check for external damage and listen for hissing sounds indicating leaks.

- Scan for Codes: Use a diagnostic scanner to check for related error codes.

Common Diagnostic Mistakes

Avoid overlooking small leaks and ensure accurate readings by calibrating your tools before use.

Testing Vacuum Levels in Brake Boosters

Manual Testing Methods

Manual testing involves checking the vacuum levels using a gauge connected to the hose.

Using a Vacuum Gauge

Attach the gauge to the vacuum hose and start the engine. Observe the reading to ensure it falls within the specified range (18-22 inHg).

Interpreting Test Results

If the reading is below the specified range, investigate potential causes, such as leaks or engine performance issues.

Maintaining Optimal Vacuum Levels

Regular Maintenance Tips

Routine inspections of the vacuum system, including hoses and connections, can prevent issues. Replace worn or damaged components promptly.

Importance of Routine Inspections

Regular inspections help identify problems early, ensuring the brake booster operates effectively and safely.

Common Maintenance Practices

Keep the engine in good condition, regularly check vacuum hoses for wear, and ensure the brake booster check valve is functioning correctly.

Repairing Vacuum-Related Issues

Identifying the Problem Source

Thorough diagnostics can help pinpoint the cause of vacuum issues, whether a leak, faulty component, or engine problem.

DIY Repair Techniques

Basic repairs, such as replacing vacuum hoses or the check valve, can be done at home with the right tools and guidance.

When to Seek Professional Help

For complex issues or if you are unsure about the repair process, consult a professional mechanic to ensure the problem is resolved correctly.

Upgrading Your Brake Booster System

Reasons to Upgrade

Upgrading can enhance braking performance, especially for high-performance vehicles or those used in demanding conditions.

Choosing the Right Upgrade

Consider factors like compatibility, performance improvements, and cost. Research different options and read reviews to make an informed decision.

Installation Process

Follow the manufacturer’s instructions carefully. If in doubt, have a professional install the upgrade to ensure it’s done correctly.

Expert Insights on Brake Booster Maintenance

Advice from Automotive Professionals

Experts recommend regular maintenance and timely repairs to keep the brake booster functioning optimally. They also suggest being aware of the signs of vacuum issues.

Common Mistakes to Avoid

Ignoring early signs of vacuum problems and delaying maintenance can lead to more severe issues and higher repair costs.

Best Practices for Longevity

Maintaining the engine, routinely inspecting the vacuum system, and addressing issues promptly can extend the life of your brake booster.

Personal Stories and Case Studies

Real-Life Examples of Vacuum Failures

Stories from drivers who experienced brake failures due to vacuum issues highlight the importance of regular maintenance and timely repairs.

Success Stories with Proper Maintenance

Those who diligently maintain their brake boosters and vacuum systems share how they’ve avoided potential accidents and maintained peace of mind.

Lessons Learned from Experience

Learning from others’ experiences underscores the importance of proactive maintenance and vigilance in ensuring brake booster reliability and safety.

Future Trends in Brake Booster Technology

Advances in Electric Brake Boosters

Electric brake boosters will likely gain popularity as electric vehicles become more prevalent due to their efficiency and compatibility with electric drivetrains.

Impact of Hybrid and Electric Vehicles

The rise of hybrid and electric vehicles is driving innovation in brake booster technology, with manufacturers focusing on integrating brake-by-wire systems for improved efficiency and performance.

Future Developments in Vacuum Systems

While electric solutions are on the horizon, traditional vacuum-based brake boosters will continue to evolve, with advancements in materials and design to enhance reliability and reduce environmental impact.

FAQs

Common Questions About Brake Boosters

- How do I know if my brake booster is failing? Look out for symptoms like increased brake pedal effort, longer stopping distances, and warning lights on the dashboard.

- Can I drive with a faulty brake booster? It’s not recommended, as compromised braking performance can pose safety risks. Has the issue been diagnosed and repaired as soon as possible?

- What causes a brake booster to lose the vacuum? Vacuum loss can be due to engine-related problems, vacuum leaks, or a faulty brake booster.

Troubleshooting Tips

- Check for vacuum leaks: Inspect hoses and connections for signs of damage or wear.

- Test engine vacuum: Use a vacuum gauge to measure the engine vacuum when idle.

- Inspect brake booster: Look for external damage and listen for hissing sounds indicating leaks.

Expert Answers

Automotive experts stress the importance of regular maintenance and prompt repairs to ensure optimal brake booster performance and vehicle safety.

Conclusion

Maintaining proper vacuum levels in brake boosters is essential for ensuring efficient braking performance and vehicle safety. By understanding the role of vacuum in brake booster operation, recognizing symptoms of vacuum-related issues, and following recommended maintenance practices, drivers can enjoy safer and more reliable braking experiences on the road.

As an Amazon Associate, I earn from qualifying purchases